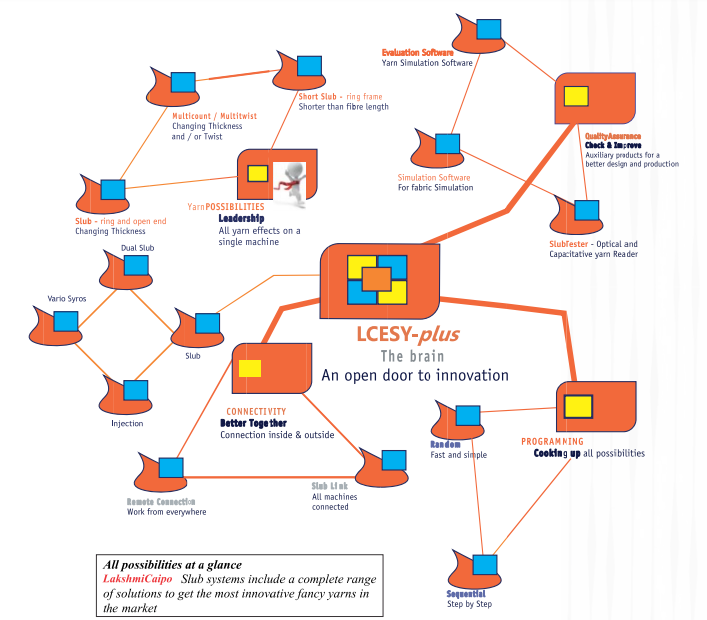

LCESY PLUS

When Unevenness is the Goal

- For years, target has been to improve yarn evenness: regularity was main requirement for selling yarn and fabric.

- But time changes. Nowadays any spinner has to be able to produce irregular yarn to be in the market. It is one of the main designing tools to match market needs.

When Irregularity means Quality

Quality is a must to spin without losing production and to process yarn at the highest warping and loom speed without breaks. To get the exact fabric appearance as per designer requirements. To be able to repeat a design when needed. This is possible only with high quality machines, combining precise mechanical construction with reliable electronic components. Only this can assure the production of sustained yarn quality and design repeatability.

Fancy yarn is a term including huge range of yams, from simple Low density random slubs Uust to "break" fabric regularity) up to slubs shorter than fibre length, colour injected stubs or high density thick stubs. Common feature is they are produced on a single process. But similarity ends here: components and requirements to get them depend on speciality to produce.

High Performances for High End yarns While for producing basic slubs, a simple system may be sufficient (i.e. in built slubs on ring frame or open end), for high end slubs yarn machines must be equipped with additional mechanisms, able to give high performance in terms of speed variation and system robustness, to allow and support special efforts without compromising neither yarn quality nor ring frame life.

Lakshmi Caipo slub

- 5 milliseconds technology : Fastest speed reaction and best performance.

- Reinforcement of drafting driving elements : your machine will not support extra loads, Lakshmi Caipo will filter them.

- Renovated electronics : new LCESY-p/us control unit combining an incredible response capacity with a very simple user interface.

- Options and possibilities : adapting to exact customer need. Options for different specialities are available from the beginning and as upgrades : your machine is always ready for future developments.

Connected to the World

Latest Lakshmi Caipo SLUB improvements in terms of software and communication provide an unmatchable level of easy use. With Colour Touch Screen and communication through Ethernet and USB, sharing information and controlling production has never been so efficient.

Explosion of Effects All what you can do with LCESY-plus

Explosion of Effects

All what you can do with LCESY-plus is New generation of LakshmiCaipo Slub allows the production of the widest range of fancy yarns, on a single machine, on a single process. Design the yarn, convert it easily on a program, feed into the machine and start production. Easy. Fast. Reliable.

BasicSlub

System controls feeding rollers to obtain:

- Slub Yarn : variation of yarn thickness (increment respect of base yarn) and its frequency.

- Negative or Reverse Slub : variation of yarn thickness (reduction in respect of base yarn) and its frequency.

- Multi Slub : combination of sections with different stub thickness in the same yarn.

ShortSlub

It allows the production of slubs shorter than fibre length for an exclusive appearance of the fabric and the final garment. Get designs different from the standards, to lead your market segment with something unique

Multicount - Multitwist

System controls feeding and production rollers to obtain:

- Multitwist yarn : variation of delivery speed only to modify yarn twist.

- Multicount yarn : variation of delivery speed and feeding speed to change twist and count.

- Combination with slub : add any slub type efficient on a multicount yarn for higher designs. Option available for Multicount – Multitwist systems.